Decontamination Systems for Sensitive Surfaces, Confined Volumes and Critical Environments

Our systems cover every CBRN decontamination and sanitization need, from protecting delicate electronic equipment to decontaminating large confined volumes and sanitizing healthcare environments, offices and emergency vehicles. Portable, safe and effective solutions, developed to reduce downtime, ensure personnel safety and meet the highest international standards.

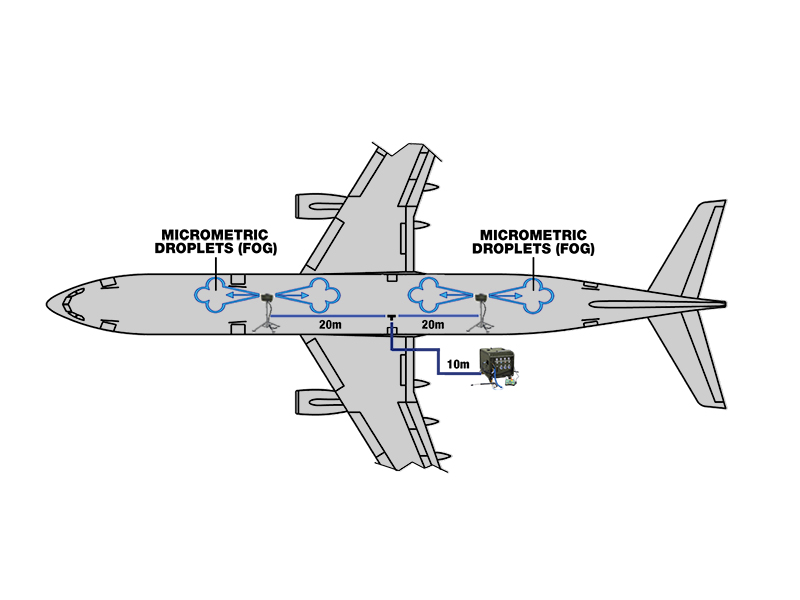

LDVX LARGE DECON VOLUME

System for CB decontamination and detoxification of confined volumes such as containers, critical infrastructure, military and passenger aircraft, cargo, headquarters, bunkers and control rooms, VIP suites, special events, underground tunnels and other indoor areas, including sensitive surfaces.

Description

LDVX acts by detoxifying air and surfaces, providing a quick and effective response in confined contaminated areas.

Easily deployable in emergencies, it is an ideal solution for decontamination from CB warfare agents and for reducing the risk of spreading endemic infectious diseases.

The system uses pressurized air as a vehicle to convey decontamination products:

-

- XP PREMIER: Cristanini patented mixture active against biological agents and acts as an activator for component (b) in decontamination against chemical warfare agents;

- H₂O₂: hydrogen peroxide.

In addition, the system allows the use of the decontaminant product BX24: Cristanini’s patented multi-spectrum CBRN decontaminant/detoxifier.

SX34 DECONTAMINATION SYSTEM

DECONTAMINATION SYSTEM FOR SENSITIVE EQUIPMENT

Decontamination system for sensitive equipment such as control panels, detectors, vehicle/boat/aircraft platforms, cockpits and individual electronic equipment (optical devices, radios, etc.).

Description

SX34 is a rapid response CBRN (chemical, biological, radiological and nuclear) decontamination system specifically designed for use on electronic components and sensitive surfaces. It uses a dry, vacuum decontamination process, eliminating the need for aggressive liquids or chemicals that could cause corrosion or electrical damage.

Housed in a rugged, shockproof case, the kit is lightweight and portable, requiring only one operator to operate. The system is ready for immediate use, enabling rapid decontamination in the field to minimize equipment downtime and ensure personnel safety. With all necessary components included, SX34 offers a complete, all-in-one solution for mission-critical equipment recovery in challenging CBRN environments.

Operating Principle

The SX34 decontaminant mixture is contained in a ready-to-use pressurized canister. The product is non-corrosive and is designed to decontaminate sensitive surfaces. Under operating conditions it can be kept at a temperature of -20 to 55 °C (-4 to 131 °F), under normal storage conditions it has a shelf life of 10 years.

The mixture interacts with CBRN agents that can be easily removed by suction equipment. Brushes and nozzles are provided to vacuum even the hardest-to-reach places. If the surface is decontaminated, it appears perfectly clean. If a whitish residue remains, the decontamination cycle can be reapplied to remove it completely, removing any doubt about the safety of using the equipment. All accessories can be decontaminated after use, using the BX24 included in the case.

VAPOR VACUUM M-8 SYSTEM

Dual-purpose steam equipment designed for biological decontamination and sanitization of offices, homes, hospitals, clinics, nursing homes and vehicle interiors contaminated with biological material.

It is ideal for ambulances, subways, trains, emergency vehicles and other similar spaces.

Also suitable for decontamination of confined spaces, air and indoor surfaces) up to 100 m³ (3531 ft³), uses steam in combination with BX65 disinfectant, effectively eliminating pathogens and harmful agents.

Description

With the combined action of steam and BX65, sanitization is effective even in the most critical conditions.

Steam, due to its thermal and mechanical energy, is an ideal means of transporting BX65 to exposed surfaces, amplifying the effectiveness of the treatment.

The system is equipped with accessories that allow operators to check the effectiveness of sanitization in real time.

The VAPOR VACUUM M-8 is composed of two separate units, steam machine and vacuum cleaner, allowing two operators to work simultaneously, combining steam and vacuum.

It is the only system on the market whose effectiveness has been recognized by the Laboratory of Microbiology and Virology of the Vita-Salute San Raffaele University of Milan, in accordance with the main European directives:

EN 17272:2020, EN 14476:2019, EN 13727:2015, EN 13624:2013, EN 14348:2005, EN 14347:2005.